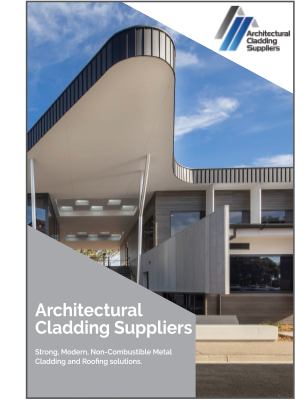

The coast is a beautiful place to live and the ultimate destination for many Australians looking for a relaxed and easy-going lifestyle. From breathtaking views to breathing in the fresh ocean air, living near the ocean can be a dream come true.

For some, it can also prove to be a challenge and one of the most difficult places to build and install metal cladding and roofing products. With the constant barrage of ocean winds and breaking surf, care and consideration need to be taken when building on the coast to avoid damage and corrosion. The salt and moisture of the coast can make construction a challenge for many architects, builders, and homeowners.

No matter where you build, near the ocean or a few kilometres away, your residence will always be exposed to the elements – wind, rain, storms, and salt. Deciding on the best metal finish can be the difference between a long-lasting and beautiful architectural design or a costly failure.

You will need to evaluate, the metal finish, coating, and performance with your architect, builder, and suppliers to ensure the finish will perform as expected for years to come.

Decisions need to be made not only on the type of substrate and metal cladding profile to be used. The colour palette and other building materials need to be carefully considered. It’s also important to consult with manufacturers for performance and warranties when deciding on the metal cladding and roofing products.

All these items need to be discussed early to ensure that the appropriate materials and finishes are specified and are available.

Metal finishes made for the coast comprise:

1. COLORBOND® Ultra steel

2. MagnaFlow

3. elZinc

4. Aluminium

1. COLORBOND® Ultra steel

With a metallic coating mass of AM150, COLORBOND® Ultra steel is suitable for coastal environments. The substrate under the paint film is ZINCALUME® coated steel which complies with the Type AM, and AZ coatings requirements of AS1397:2011.

The colour coat complies with AS2728. Highly recommended in areas where the structure will be located 100 to 200 meters from breaking surf where there is salty spray in the air.

COLORBOND® Ultra steel delivers all the benefits associated with standard COLORBOND® steel – comprising:

- Strict adherence to grades, chemical composition and strength is provided – meeting Australian Standards.

- BlueScope metallic coating with Activate® to deliver resistance to corrosion.

- Specially designed top coat with exterior grade paint is baked on to the product to help to ensure any resistance to flaking, blistering or chipping in diverse weather conditions or environments. This also helps to ensure the finish retains its look and beautiful subtle finish for longer.

COLORBOND® Ultra steel is available in the following six colours: Dune®, Monument®, Surfmist®, Wallaby®, Windspray®, and Woodland Grey®.

If you’d like to read more information about COLORBOND® Ultra steel, the datasheet can be found here

In case you’re planning to build within 100 meters from the breaking surf, the SUPERDURA® Stainless steel option is highly recommended. This finish is considered to be the most durable and is designed specifically for very severe coastal conditions.

If you’d like to read more information about SUPERDURA® Stainless steel, the datasheet can be found here

2. MagnaFlow

MagnaFlow takes standard zinc/aluminium alloy-coated steel substrate to the next level with the addition of magnesium. This enables the zinc to ‘flow’, which seals the cut edges, preventing exposure to premature corrosion.

With a substantial 210gms/m2 coating this makes it ideal for harsher environments and those nearer the coast. MagnaFlow has very good colour and gloss retention and is suitable for roofing, cladding, and rainwater goods.

MagnaFlow is ideal for exterior environments where corrosion levels are moderate. MagnaFlow is available in all the same great colours as ZinaCore.

ColorCote MagnaFlow X is ideal for exterior applications such as severe marine structures where there is a high risk of deterioration from corrosive elements in the environment. The ‘X’ paint system provides added protection and is only available in a restricted colour range and availability may be subject to longer than standard lead times.

If you’d like to read more information about MagnaFlow, the datasheet can be found here

3. elZinc

elZinc Advance is an ideal solution to provide long-term protection to roofs and facades located in especially corrosive environments.

elZinc Advance consists of rolled architectural titanium-zinc manufactured in accordance with requirements established by ASTM B69-13. The zinc is then coated on its outside-facing layer with a transparent 35-micron organic layer.

This product is designed to broaden the lifespan of the zinc while leaving its appearance unaltered.

Some key benefits include:

- A barrier effect – elZinc Advance is resistant to corrosive atmospheric elements.

- An inhibitor effect – elZinc Advance minimises adhesion of salt and inorganic substances which may cause white oxidation in coastal areas.

elZinc Advance is available in the following five colours: Graphite®, Slate®, Crystal®, Lava®, and Oliva®.

If you’d like to read more information about elZinc Advance, the datasheet can be found here

4. PREFA Aluminium

PREFA Aluminium – PREFALZ® is an effective option for exterior architectural cladding in coastal environments – offering numerous possibilities in terms of design, colour and shape. Supplied in a total of 18 colours and in plain aluminium with a smooth or stucco surface, as required.

Some key benefits include:

- Long service life – non-corrosive in coastal environments

- Versatility – from cureved cladding profiles and arched roofs to complex extensions, domes or large-scale projects

- Available in the standard colours

- Fully recyclable

- Also available with protective film on request (smooth surface only)

- Easy to work with, strong load-bearing capacity

- Prefalz® is non-combustible (A1)

If you’d like to read more information about PREFA Aluminium – PREFALZ®, the brochure can be found here

Your choice of metal cladding products will largely hinge on the overall design and aesthetic of your build.

The desired appearance, functional requirements, vision, and budget of your coastal project will determine the finish you select.

Collaboration between architects, specifiers, manufacturers, fabricators, and installers is critical. This will help ensure the selected material finish and metal cladding/roofing system will provide durability and a long-lasting appearance to ultimately deliver the best outcome for the homeowner.

To learn more about our metal cladding finishes and products, click below to download our Brochure and Data Sheets:

ACS Company Brochure

ACS Standing Seam Data Sheet

ACS Interlocking Data Sheet

ACS Nailstrip Data Sheet

ACS Snaplock Data Sheet

ACS Weatherboards Data Sheet

ACS Shingles Data Sheet

ACS Flatlock Data Sheet

As every architectural project is different if you require custom advice the ACS team looks forward to working with you to realise your vision. This article has been written for informational purposes, ensure you seek the advice of your architect, specifier, manufacturer, building contractor, and/or professional installer.