WALL CLADDING AND ROOFING PRODUCTS MADE FROM VMZINC®

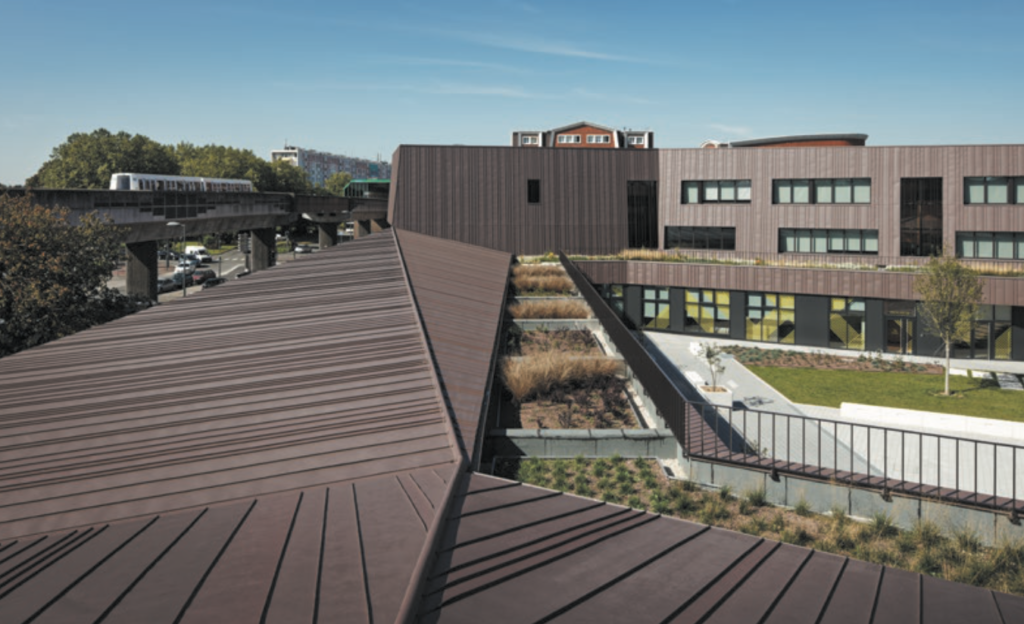

VMZINC® provides the freedom to create architectural masterpieces. The flexibility, malleability, and versatility of zinc, combined with its elegance make it the perfect material for innovative building projects.

As architects continue to seek sustainable materials, zinc will continue to be specified in a diverse range of uses including residential, commercial, rural, government, and a variety of interior applications. VMZINC® as a chosen finish will demonstrate extraordinary adaptability. When used appropriately this extraordinary material finish will enhance building designs and give them a memorable vibrancy.

Making your next project a success with VMZINC®

According to VMZINC® – the following basic principles should be taken into account to make your next project a success:

- Ventilation: ensure the air gap located beneath the support allows the evacuation of humidity caused by internal condensation.

- Compatibility: Certain products when placed in contact with zinc can have detrimental effects on the appearance and integrity of the zinc.

- Expansion: Any work involving VMZINC® must allow it to expand and contract freely.

- Handling: Ensure that the zinc is not handled in an area with great temperature variations.

THE KEY ADVANTAGES OF VMZINC®

- Diverse Finishes: A varied range of aspects and colours.

- Certification: Manufactured at ISO 14001 ISO 9001.

- Durability: Due to the self-protective coating, VMZINC® rolled zinc has a lifespan of 80 to more than 100 years.

- Recyclable: Rolled zinc is 100 % recyclable through simple re-melting and has an actual recycling rate of à 98.9 % in France.

- Maintenance: Very little cleaning and maintenance required.

- Environment: VMZINC® makes numerous Product Environmental Declarations (PEDs) available to its clients. These PEDs comply with the EN 15804 standard and are checked by third parties.

The pure magic of Zinc

Zinc is very malleable and can meet virtually all architectural needs. It offers the freedom to craft architectural masterpieces that are difficult to achieve with other construction materials.

Added to this, the VMZINC® range of colours gives architects, installers, and builders multiple options to match their creativity. In addition to offering creative freedom, zinc is resistant, durable, and sustainable for the building process. VMZINC® is 100% recyclable and can be recycled indefinitely, putting it far ahead of many other construction materials.

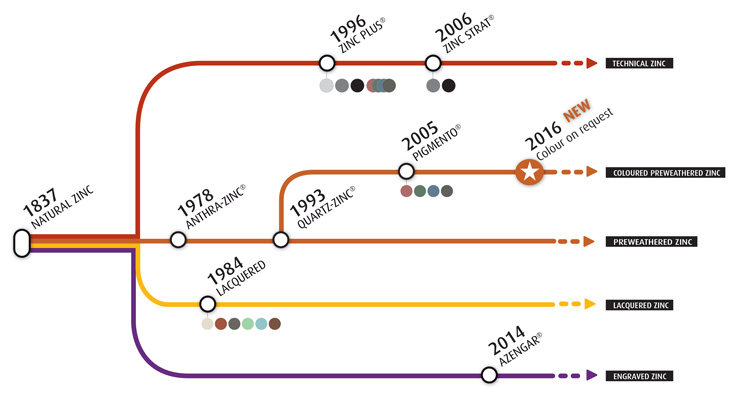

Diversity of finishes

VMZINC is building the future with an unsurpassed variety of zinc colours for innovative architectural visions. VMZINC building products are highly flexible, malleable, and durable. They are available in 10 pre-weathered finishes as well as mill-finish Natural Zinc. An elegant partner for many building materials. Zinc can be embossed, perforated, and incorporated texture helping to create imaginative designs.

In order to ensure that the envelope of your building or renovation project meets your specifications, VMZINC offers a variety of surface aspects:

VMZINC® Brochures

VMZINC® Building Principles Brochure

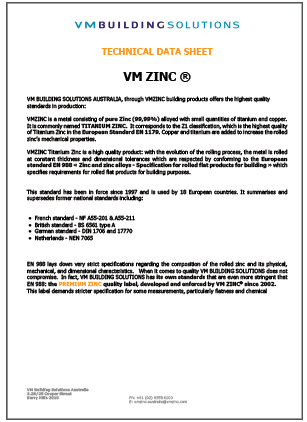

VMZINC® Technical Data Sheet

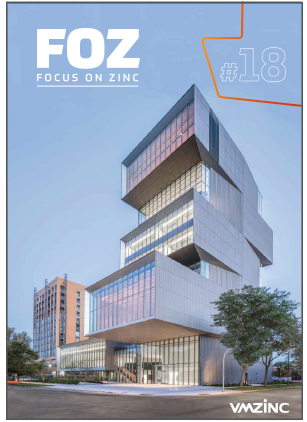

VMZINC® Focus on Zinc Brochure

VMZINC® Maintenance

VMZINC® Sustainable Building Brochure

VMZINC® Focus on Zinc Brochure

NEED MORE INFORMATION

Speak with the ACS project team to learn more about our architectural cladding profiles, finishes, performance, installation process, technical information, price, and any general metal cladding questions you may have.