Standing Seam metal cladding and roofing manufactured and supplied by Architectural Cladding Suppliers has a modern and seamless design element to offer something exceptional for your next project.

Standing Seam is a simple-looking metal cladding and roofing profile. One of the most versatile cladding systems available, Standing Seam can be installed across numerous applications, from roofing to façades, soffits, and even on internal walls as an architectural feature finish. This is achieved through our expertise in forming individual panels into tapered, flat, curved, concave, or convex shapes to perfectly suit the application.

ACS recommends installing a “breathable vapour” membrane to act as a second line of defence to stop any water ingress as well as allowing the building to breathe. Stop ends and/or hooks to each panel are also recommended, along with the appropriate clips to fix the Standing Seam panels into place. A dedicated seam closing tool must be used to close each rib and complete the installation. If you are unsure, please contact us prior to ordering.

Standing Seam metal cladding and roofing can achieve seamless roof-to-wall details, modern concealed gutters, and a modern architectural finish for your next project.

The key benefits of Standing Seam metal cladding and roofing include:

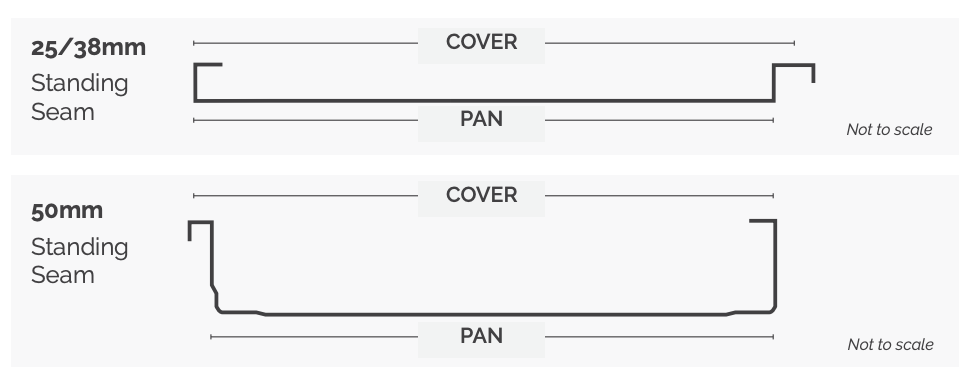

- Attractive modern and seamless aesthetic with multiple panel height options: 25mm, 38mm, and 50mm. The 50mm option has clip relief in the pan of the panel.

- All of our cladding coil material is deemed non-combustible by their respective manufacturers, making our Standing Seam panel suitable for use in fire/BAL rated applications in conjunction with a suitable wall/roof build-up.

- Minimal material maintenance, providing peace of mind for the installer, builder, and end-user client.

- Versatile design and installation options are available for Standing Seam – with the ability to be manufactured in various width combinations for installers.

- Using the 205mm cover width option helps reduce the chance of oil canning. The cover widths can be customised, if required, up to 530mm.

- Standing Seam allows for material expansion and contraction – delivering a high-quality long-term cladding solution.

Architectural Cladding Suppliers offer the fabrication flexibility our installers require to keep their projects running smoothly. Architectural design requirements such as precise pan widths allow for the custom supply of metal cladding and roofing panels to create seamless and simply beautiful assembled facades.

Cost-effective pan sizes for COLORBOND® steel 25 mm Standing Seam (with a 70mm seam allowance) comprise:

- 230 mm

- 330 mm

- 530 mm

Cost-effective pan sizes for COLORBOND® steel 38 mm Standing Seam (with a 95mm seam allowance) comprise:

- 205 mm

- 305mm

- 505 mm

Cost-effective pan sizes for COLORBOND® steel 50 mm Standing Seam (with a 118mm seam allowance) comprise:

- 282 mm

- 482 mm

With Standing Seam, you have the choice of many different materials and finishes to work with.

Standing Seam fabricated and supplied by Architectural Cladding Suppliers offers great material and finish choices. ACS operates on project-based production cycles tailored to the exact requirements and specifications of our installers. No stock of any of our metal cladding and roofing profiles is held on-site.

This fabrication process reduces waste, increases efficiencies, and allows our installers, builders, architects, and DIY trades/homeowners, to select the profile required in the size, material, and finish they desire for their next project.

Standing Seam can be manufactured using a diverse range of metals available – including:

- COLORBOND® steel

- GALVABOND® steel

- ZINCALUME® steel

- PREFA Aluminium

- Aurubis

- elZinc®

- VMZINC®

- Unicote® & Unicote® Lux

- MagnaFlow, ColorCote & UniZinc™

Achieve a modern and seamless installation with Standing Seam metal cladding and roofing.

Standing Seam provides installers with the flexibility and freedom to tailor their work. To learn more, refer to the product specifications below.

Product Specifications

| Panel Heights available | 25mm, 38mm and 50mm* panel heights available |

| Length of Panel | Panel lengths available from a minimum 500mm, dependant on material selection |

| Cover Widths available | 205mm – 530mm pan widths from rib to rib (material dependant) |

| Substrate Requirements | Substrate options available for wall and roof applications |

| Tolerance (mm) | Sheet length: +/- 7mm and Covering width: +/- 7mm |

| Stop End and/or Hook | Recommended by ACS |

| Fire Rated/BAL Applications | Suitable for use in fire-rated and BAL applications in conjunction with a suitable wall/roof build-up ** |

* Note: 50mm product has clip relief in the pan of the panel.

** Note: For further information and expert advice please contact Architectural Cladding Suppliers.

Standing Seam Profile

Standing Seam Data Sheet

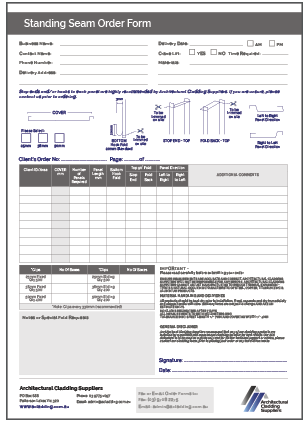

Standing Seam Order Form

At ACS, our fabrication process is tailored to our clients’ project specifications, reducing waste, allowing for flexibility, and most importantly providing installers, builders, and architects the freedom to select the material, finish they desire, along with the size and style they prefer.

Our project team is here to support our clients. If you require custom advice, we can discuss your project specifications and work with you to fabricate to your individual requirements.