Snaplock metal cladding manufactured and supplied by Architectural Cladding Suppliers has a classic and traditional design element to offer something remarkable for your next project.

Snaplock metal cladding panels offer architects, builders, and installers a seamless finish without the need for specialist tools – making it a popular profile for residential and commercial building projects. Snaplock is held in position using a clip (similar to standing seam), enabling the panel to expand and contract. This allows a more diverse range of materials to be utilised and is perfect for use in extreme weather landscapes.

The key benefits of Snaplock metal cladding include:

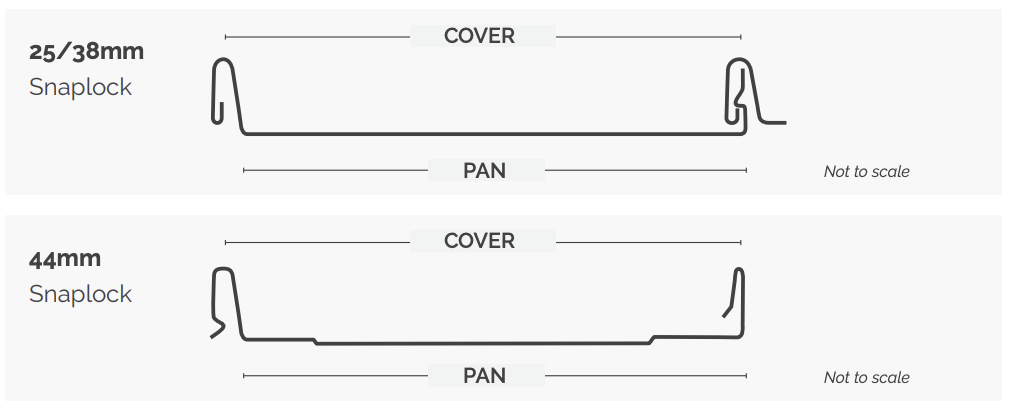

- Attractive modern look with multiple panel height options: 25mm, 38mm, and 44mm. The 44mm option has clip relief in the pan of the panel.

- Versatile design and install options are available for Snaplock – with the ability to be manufactured in various width combinations for installers.

- Minimal material maintenance, providing peace of mind for the installer, builder, and end-user client.

- Snaplock is suitable for use in fire-rated and BAL applications in conjunction with a suitable compliant wall build-up by others.

- Using the 205mm and 305mm cover width options helps reduce the chance of oil canning. The cover widths can be customised if required, up to 525mm.

- Snaplock has been tested in accordance with Australian Standard AS 4040.2-1992 – “Method of testing sheet roof and wall cladding for non-cyclonic regions” and therefore satisfies AS/NZS 1562.1:1992 Design & Installation of sheet roof and wall cladding – metal. For more information, download our Compliance Data Sheet from the technical library.

- Snaplock metal cladding allows for material expansion and contraction – delivering a high-quality long-term cladding solution.

With Snaplock metal cladding, you have the choice of many different materials and finishes to work with.

ACS recommends installing a “breathable vapour” membrane to act as a second line of defence to stop any water ingress as well as allowing the building to breathe. Stop ends and/or hooks to each panel are also recommended. If you are unsure, please contact us prior to ordering.

Snaplock can be manufactured using a diverse range of metals available – including:

- COLORBOND® steel

- GALVABOND® steel

- ZINCALUME® steel

- PREFA Aluminium

- Aurubis

- elZinc®

- VMZINC®

- Unicote® & Unicote® Lux

- MagnaFlow, ColorCote & UniZinc™

Achieve a striking and remarkable installation with Snaplock metal cladding.

This metal cladding profile provides installers with the flexibility and freedom to customise their work. To learn more, refer to the product specifications below.

Product Specifications

| Panel Heights available | 25mm, 38mm and 44mm * panel heights available |

| Length of Panel | Panel lengths available from a minimum 500mm, dependant on material selection |

| Cover Widths available | 225mm – 525mm widths from rib to rib (material dependant) |

| Substrate Requirements | Substrate requirements are a metal tophat no less than 0.55 BMT zincalume and spaced at a maximum of 900 centres for wall application. Roofing recommendation is 19mm construction grade plywood for best finish ** |

| Tolerance (mm) | Sheet length: +/- 7mm and Covering width: +/- 7mm |

| Stop End and/or Hook | Recommended by ACS |

| Fire Rated/BAL Applications | Suitable for use in fire-rated and BAL applications in conjunction with a suitable wall/roof build-up ** |

* Note: 44mm product has clip relief in the pan of the panel.

** Note: For further information and expert advice please contact Architectural Cladding Suppliers.

Snaplock Profile

Snaplock Data Sheet

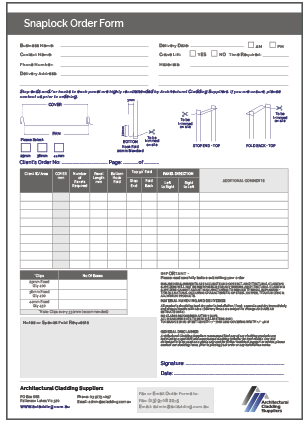

Snaplock Order Form

At ACS, our fabrication process is tailored to our clients’ project specifications, reducing waste, allowing for flexibility, and most importantly providing installers, builders, and architects the freedom to select the material, finish they desire, along with the size and style they prefer.

Our project team is here to support our clients. If you require custom advice, we can discuss your project specifications and work with you to fabricate to your individual requirements.