Oil canning in metal cladding and roofing explained.

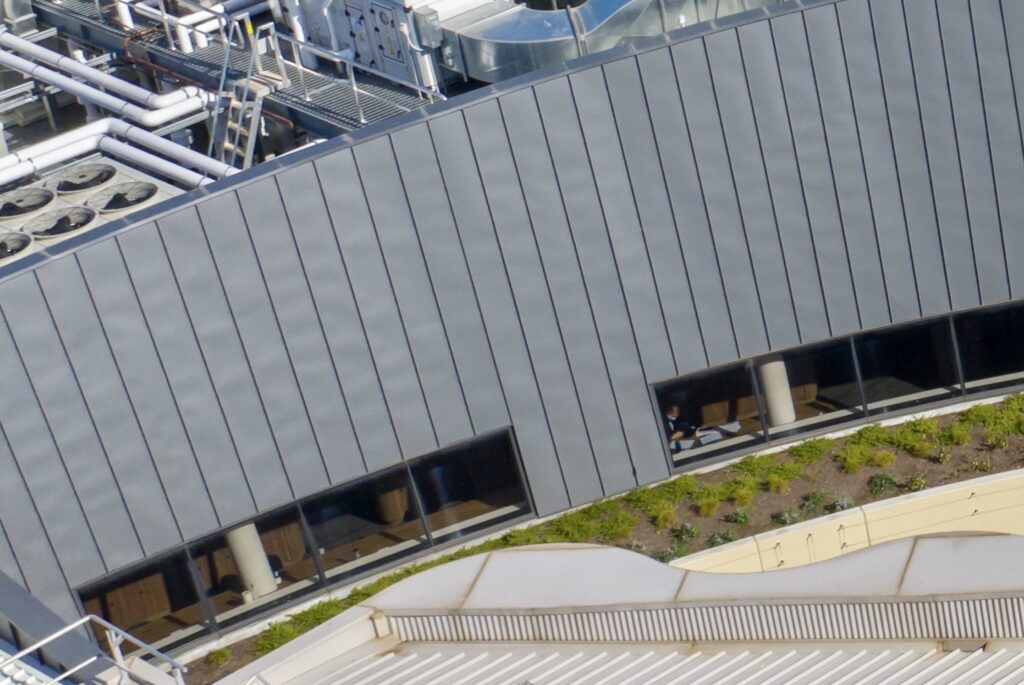

Oil Canning can be defined as a ‘wavy distortion’ in the flat areas of metal cladding and roofing panels. This waviness, rippling, or buckling is commonly seen in the broad flat area of a metal wall or roof. It can occur on all types of metal, including copper, aluminium, zinc, and steel.

It is important to understand oil canning is not classed as a defect of the metal wall or roof panel and is seen as more of an aesthetic issue that people will either like or dislike. All dependent on the material, finish selected, thickness and panel width, manufacturing and installation process; and changing lighting conditions can affect how visible these distortions are.

Oil canning can be more visible during certain times of day and in certain seasons based upon the angle at which sunlight hits the wall or roof, and based upon the temperature differential.

The key causes of Oil Canning

The key causes of oil canning can vary. Here are a few reasons why your metal roof or wall may be experiencing oil canning:

- Stress During Coil Production – may contribute to oil canning. Due to the small gaps within the rollers, there can sometimes be uneven distribution of stress. The most common example is when the coil is longer in the middle of the strip which creates ripples or waves near the mid-coil area. Other examples include a wavy edge where the coil is longer along the edge of the strip; and a camber where there is a deviation on the side edge.

- Slitting and Fabrication – the slitting of a master coil may redistribute residual forces. The coil’s response to slitting and fabircation may increase oil canning. Residual stresses may be developed whilst fabrication or rollforming.

- Uneven or Poorly Installed Substrates – may cause slight waves, which could eventually produce more visible distortions. The appearance of oil canning may be enhanced when a substrate is not straight. A properly installed substrate is a key element in ensuring that oil canning is minimised.

- Structural Supports – that are made and installed within allowable tolerances may create a uneven or contoured bearing surface. Stresses induced while panels conform to this surface may contribute to oil canning.

- Installation Process – may create oil canning. Fasteners could be overdriven, driven in at the wrong angle, or even the incorrect clip systems may be used. The panels themselves could also be misaligned, leading to uneven stresses.

- Metal Panel Widths and Lengths – keeping metal panel widths and lengths to a manageable size, can minimise oil canning risk.

- Thermal Expansion & Contraction – if your metal panels have limited space to expand and contract with fluctuating temperatures, this uneven stress can produce oil canning.

- Material Storing & Handling — before installation, it’s critical to ensure materials are stored and handled appropriately so they do not bow.

Minimising and Controlling the effects of Oil Canning

Industry research continues to evolve on improved production, fabrication, and installation methods to help minimise and control the effects of oil canning. Here are some tips to help:

- Material Selection – by selecting a thicker gauge material greater rigidity and strength will be delivered. This may help with minimising movement after installation, leading to lessening the effects of oil canning. In addition, by choosing more narrow widths may reduce the appearance of oil canning. With less space between panels widths, there may be minimised oil canning effects. By choosing supporting products such as stop ends on interlocking panels can help to reduce the risk of oil canning.

- Matt and Textured Finishes – when identifying the appropriate finish to be used, moving forward with a matt, low-gloss finish may help reduce the reflectivety. This may help make oil canning less visible. A textured finish may also help minimise the appearance of waves.

- Handling and Storage – proper handling and storage is one of the most important considerations and should be addressed in production, transportation and all installation activities.

- Tailored and Planned Installation – using fasteners and clips that allow panels to float without causing thermal stresses may contribute to controlling oil canning on metal cladding and roofing panels. Installation practices to avoid any misalignment or over-engagement of panels, overtightening of fasteners and ensure adequate allowance is made for thermal or structural movement. Using fluting or beading to strengthen the tray and working with a level substructure may also help deliver the best possible installation and minimise the effects of oil canning.

Your choice of metal cladding products will largely hinge on the overall design and aesthetic of your build.

Collaboration between architects, specifiers, manufacturers, fabricators, and installers is critical. This will help ensure the selected material finish and metal cladding/roofing system will provide durability and a long-lasting appearance to ultimately deliver the best outcome for the homeowner.

It is important to understand that sometimes oil canning is unavoidable and there is no guarantee that your metal panels will not experience the effects of oil canning. Considering that many uncontrollable factors are involved, no supplier can assure the total elimination of oil canning.

Oil canning is not a defect of the material and is perceived more as an aesthetic issue that you will either like or dislike. The best way to prevent the effects of oil canning is to follow the suggested tips listed above before installation and work closely with all project stakeholders.

To learn more about our metal cladding finishes and products, click below to download our Brochure and Data Sheets:

ACS Company Brochure

ACS Standing Seam Data Sheet

ACS Interlocking Data Sheet

ACS Nailstrip Data Sheet

ACS Snaplock Data Sheet

ACS Weatherboards Data Sheet

ACS Shingles Data Sheet

ACS Flatlock Data Sheet

As every architectural project is different if you require custom advice the ACS team looks forward to working with you to realise your vision. This article has been written for informational purposes, ensure you seek the advice of your architect, specifier, manufacturer, building contractor, and/or professional installer. For any further information and advice please contact the ACS project team directly.