Interlocking metal cladding manufactured and supplied by Architectural Cladding Suppliers has a fresh and simple design element to offer something truly special for your next project.

Interlocking metal cladding panels can be installed horizontally, vertically, or even diagonally to add a dramatic, sophisticated look to both residential and/or commercial applications. From bespoke residential builds to multi-townhouse developments and large-scale commercial buildings, this profile delivers a seamless and simply beautiful architectural aesthetic.

The key benefits of Interlocking metal cladding include:

- Versatile design and install options are available for Interlocking – with the ability to be manufactured in various face and joint width combinations for installers.

- Interlocking is suitable for use in fire-rated and BAL applications in conjunction with a suitable compliant wall build up by others.

- Interlocking has been tested in accordance with Australian Standard AS 4040.2-1992 – “Method of testing sheet roof and wall cladding for non-cyclonic regions” and therefore satisfies AS/NZS 1562.1:1992 Design & Installation of sheet roof and wall cladding – metal. For more information download our Compliance Data Sheet from the technical library.

- Using the 205mm and 305mm cover width options helps reduce the chance of oil canning. The cover widths can be customised if required, up to 505mm.

- Interlocking metal cladding allows for material expansion and contraction – delivering a high-quality long-term cladding and roofing solution.

- Low level of maintenance after installation – providing peace of mind for both the installer, builder,, and end-user client.

- Interlocking is available in a 25mm panel height – suitable for both commercial and residential projects providing a striking architectural finish.

With Interlocking metal cladding you have the choice of many different materials and finishes to work with.

Interlocking is available in a 25mm panel height and a range of different panel lengths, depending on material selection. ACS recommends limiting the length to 4 metres where possible. Whatever the application there will be no visible fixings – providing a streamlined architectural aesthetic.

Interlocking can be manufactured using a diverse range of metals available – including:

- COLORBOND® steel

- GALVABOND® steel

- ZINCALUME® steel

- PREFA Aluminium

- Aurubis

- elZinc®

- VMZINC®

- Unicote® and Unicote® Lux

- MagnaFlow, ColorCote® & UniZinc™

Achieve a seamless and striking installation with Interlocking metal cladding.

Interlocking can be laid directly onto a multitude of sub-structure variations, from top hats, plywood even metal trapezoidal sheeting. This metal cladding profile provides installers with the flexibility and freedom to customise their work. To learn more refer to the product specifications below.

Product Specifications

| Panel Heights available | 25mm panel height (depth of recess) |

| Length of Panel | Panel lengths available from a minimum 500mm, dependant on material selection – recommended maximum 4000mm length* |

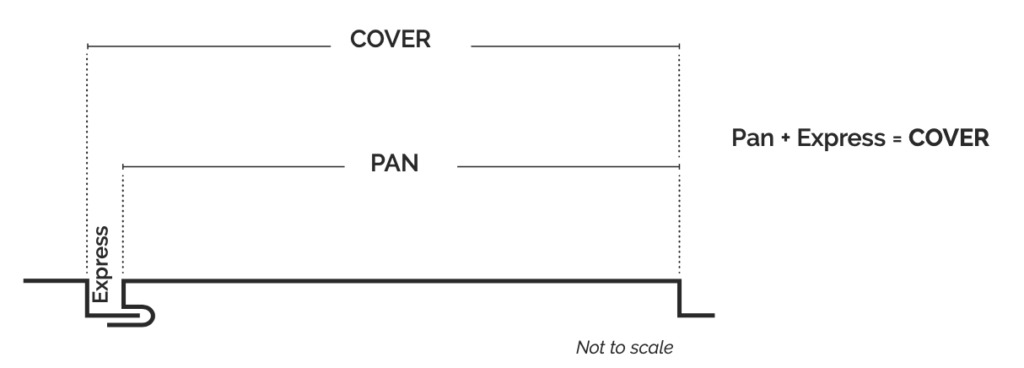

| Cover Widths available | 205mm – 505mm widths (material dependant) with up to a 25mm recess between panels |

| Substrate Requirements | Substrate requirements are a metal tophat no less than 0.7 BMT zincalume and spaced at a maximum of 600 centres * |

| Tolerance (mm) | Sheet length: +/- 7mm and Covering width: +/- 7mm |

| Stop End and/or Hook | Recommended by ACS |

| Fire Rated/BAL Applications | Suitable for use in fire-rated and BAL applications in conjunction with a suitable wall build-up * |

* Note: For further information and expert advice please contact Architectural Cladding Suppliers.

Interlocking Profile

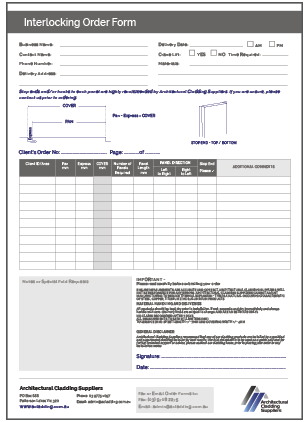

For more information download the ACS Interlocking Data Sheet and the ACS Interlocking Order Form.

At ACS, our fabrication process is tailored to our clients’s project specifications, reducing waste, allowing for flexibility, and most importantly providing installers, builders, and architects the freedom to select the material, finish they desire, along with the size and style they prefer.

Our project team is here to support our clients. If you require custom advice, we can discuss your project specifications and work with you to fabricate to your individual requirements.