Fire Resistant and Non-Combustible Metal Cladding

Fire performance is a common query from architects, builders, installers, and end-users regarding our product range and the materials they are manufactured from. Cladding can play a key role in helping protect your building from the risk of fire, especially in Australian rural settings. Selecting metal cladding products made from materials that are classed as non-combustible and fire-resistant is a major consideration for any type of project – residential and/or commercial.

National Construction Code (NCC) 2019

The National Construction Code (NCC) sets out technical provisions for the design, construction, and performance of buildings throughout Australia, including criteria for the assessment of building elements under fire conditions.

A 2020 advisory note added additional clarification around aspects such as internal linings on external walls and the use of render to the National Construction Code (NCC). The overarching purpose of these rule changes was to prevent the spread of fire via external cladding applications for all types of projects.

An extensive audit of at-risk buildings throughout Australia a few years ago has led to a major re-think of how external cladding is specified and installed.

Compliance to AS 1562.1:2018 and AS 1530.1

If you’re designing and involved in the construction of a new build or even completing a renovation/addition you will need to comply with the new requirements set in AS 1562.1:2018 and AS 1530.1.

All external walls need to be made of non-combustible materials. External walls are those walls deemed integral to the building construction and include elements such as insulation, substrates, facades, internal lining, and framing.

Cladding is classed as non-combustible if it passes the testing requirements of AS1530.1.

The requirements for this test allow a cladding product to contain no more than 0.5% combustible material. In practical terms, a material is considered combustible if it flames for more than 5 seconds when subjected to a fire for 30 minutes. Materials that may not meet these strict requirements may be deemed fit for purpose where the flammability is considered to be extremely low. These products include:

- Plasterboard

- Perforated gypsum lath with a normal paper finish

- Fibrous-plaster sheet

- Fibre-reinforced cement sheeting

You may also use pre-finished metal sheeting where the combustible surface finish does not exceed 1mm thickness and where the Spread-of-Flame Index of the product is not greater than 0. And bonded laminated materials may also be acceptable provided that: each laminate layer must be non-combustible, no adhesive layer may exceed 1mm in thickness and the overall thickness of the adhesive layers must not exceed 2mm. The Spread-of-Flame Index cannot exceed 0 and the Smoke-Developed Index must not exceed 3 when the laminated material as a whole is tested.

Source: NCC – Australian National Construction Code

The example below is of BlueScope’s fire resistance information available, our other materials/suppliers have their own data and can be found at their respective websites. We can source this information when required.

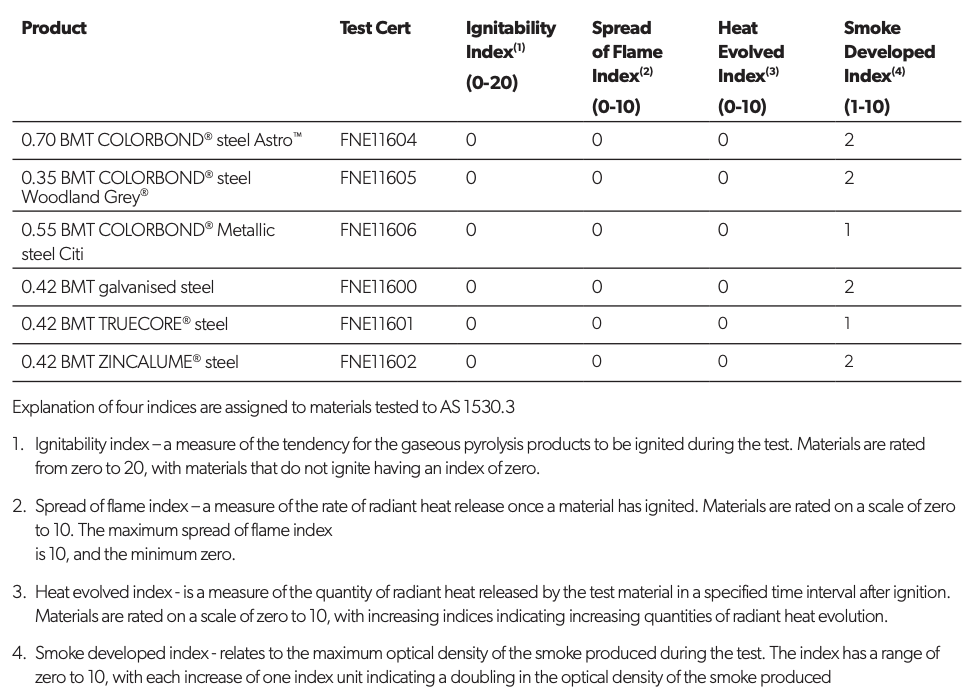

Products manufactured from BlueScope materials (detailed below) all have a Spread-of-Flame index of 0 (zero) and 1 to 2 for Smoke Developed and as such are considered non-combustible materials in accordance with the NCC.

BlueScope commissioned CSIRO to undertake a comprehensive range of testing to determine the Flammability of various permutations of COLORBOND® steel, ZINCALUME® steel, and galvanised steel material. These tests have been conducted in accordance with AS1530.3: SIMULTANEOUS DETERMINATION OF IGNITABILITY, FLAME PROPAGATION, HEAT RELEASE, AND SMOKE RELEASE.

The results of this testing are summarised in this table:

Additional information in relation to the use of COLORBOND® steel products in bush-fire prone areas may be sourced from The BlueScope Fact File Steel cladding details or bushfire-prone construction at www.steelselect.com

Is your metal cladding suitable to use in a BAL Zone?

Nominating an area as a BAL (Bushfire Attack Level) Zone can take into consideration a variety of items including the slope of the land, the type and quantity of vegetation in its surroundings and how close it is to other buildings.

So not all building scenarios will involve a BAL requirement, or a fire-rated wall application. However, as the metal materials that we use to produce our cladding profiles are all deemed non-combustible, they can be used in both applications, in conjunction with the appropriate building regulations being followed.

Important Note:

Architectural Cladding Suppliers does not supply a fire-rated wall system, and can only give advice in regard to the combustibility properties of the metal material selected. Our team can supply the appropriate fire test certificates from the manufacturer of the material. When design professionals are looking at an FRL build-up, you will need to consult the relevant and appropriate construction information that relates to their class or type of building.

Can I use your metal cladding on a fire-rated wall?

Fire-rated walls are a requirement where buildings are located adjacent to each other, either with a small space between external walls or sharing a common wall.

Fire-rated walls are generally rated using the FRL. This measures the material’s ability to withstand fire across the following key aspects:

- Structural adequacy

- Integrity

- Insulation

The result of these tests will show the number of minutes each aspect would survive a test fire. The FRL requirement is very much in keeping with the non-combustible cladding requirement: both view an external wall as the sum of its parts.

Important Note:

You must check your intended designs and building plans comply with local council/building code requirements.

Your choice of metal cladding products will largely hinge on the overall design and aesthetic of your build.

At ACS, we have an extensive range of metal cladding, a diverse colour range, and flexible design options to give you some stunning creative options. And you’ll have the assurance knowing your metal cladding is non-combustible, durable, and there to protect you from the weather as well as provide exceptional fire-rated performance.

Collaboration between architects, specifiers, manufacturers, fabricators, and installers is critical. This will help ensure the selected material finish and metal cladding/roofing system will provide protection, durability, and a long-lasting appearance to ultimately deliver the best outcome for the homeowner.

To learn more about our metal cladding products and finishes – click here

As every architectural project is different if you require custom advice the ACS team looks forward to working with you to realise your vision. This article has been written for informational purposes, ensure you seek the advice of your architect, specifier, manufacturer, building contractor, and/or professional installer. For any further information and advice please contact the ACS project team directly.