INTERLOCKING

Interlocking / V25 is a contemporary metal cladding profile that has a fresh and simple design element. Used predominantly in-wall and soffit cladding applications, panels can be installed horizontally, vertically, or even diagonally to add a dramatic, sophisticated look to any building façade.

Interlocking/V25 panel is lightweight and can be installed either internally or externally. This provides architects and designers with multiple design possibilities. The panel can be laid directly onto a multitude of sub-structure variations, from top hats, plywood even metal trapezoidal sheeting. This system has the flexibility to be used on residential and commercial projects due to its simplistic and sleek appearance. With the ability to be manufactured in various face and joint width combinations, the Interlocking/V25 panel provides a striking and modern element to any project.

Product Highlights

- Non-combustible metal cladding profile

- Versatile design and install options are available

- Streamlined and flat facade aesthetic with concealed fixings

- Suitable for wall cladding and soffit only

- Suitable in an extensive material range

Testing

This product has been tested in accordance with Australian Standard AS 4040.2-1992 – “Method of testing sheet roof and wall cladding for non-cyclonic regions” and therefore satisfies AS/NZS 1562.1:1992 Design & Installation of sheet roof and wall cladding – metal. For more information download our Compliance Data Sheet from the technical library.

Interlocking Metal Cladding Specifications

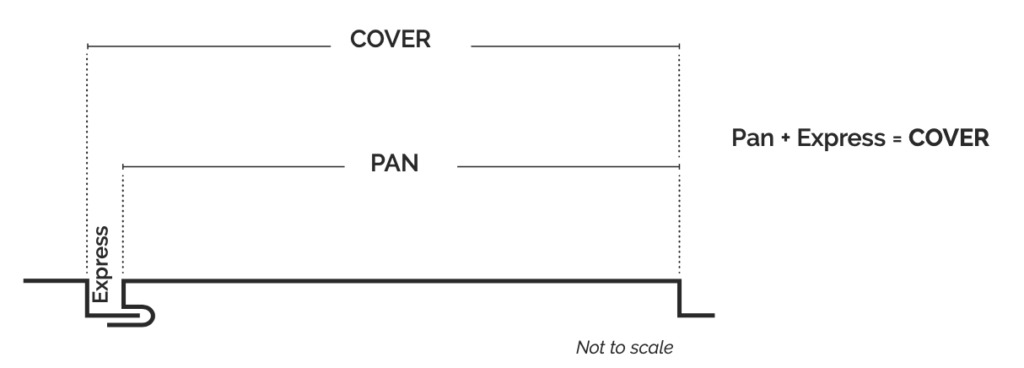

| Panel Heights available | 25mm panel height (depth of recess) |

| Length of Panel | Panel lengths available from a minimum 500mm, dependant on material selection – recommended maximum 4000mm length * |

| Cover Widths available | 205mm – 505mm pan widths (material dependant) with up to a 25mm recess between panels |

| Substrate Requirements | Substrate requirements are a metal tophat no less than 0.7 BMT zincalume and spaced at a maximum of 600 centres * |

| Tolerance (mm) | Sheet length: +/- 7mm and Covering width: +/- 7mm |

| Stop End and/or Hook | Recommended by ACS |

| Fire Rated/BAL Applications | Suitable for use in fire-rated and BAL applications in conjunction with a suitable wall build-up * |

* Note: For further information and expert advice please contact Architectural Cladding Suppliers.

Technical Support

Architectural Cladding Suppliers are here to help you. We can manufacture and provide everything that is required to complete your project from our cladding profiles to all the associated accessories and flashings via our sister company, PPC Flashings. For further information or support with flashings please contact the PPC Flashings team.

As every architectural project is different, if you require custom advice, we can discuss your project specifications and will work with you to fabricate to your individual requirements. For any further technical support please contact Architectural Cladding Suppliers.

Installation

We cannot guarantee that your metal panels will not experience the effects of what is commonly referred to as oil canning. Oil canning can occur on all types of metal and is not considered a panel defect. For more information please refer to our article on oil canning.

ACS recommends installing a “breathable vapour” membrane to act as a second line of defence to stop any water ingress as well as allowing the building to “breathe”. Any flashings required can be sourced from PPC Flashings.

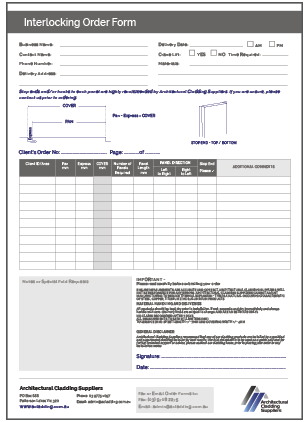

Stop ends and/or hooks to each panel are highly recommended by Architectural Cladding Suppliers. If you are unsure, please contact us prior to ordering.

Do not continue if the installation does not seem right, contact Architectural Cladding Suppliers.

Interlocking Profile

Interlocking Data Sheet

Interlocking Order Form

GENERAL DISCLAIMER:

Architectural Cladding Suppliers recommend that any of our cladding products are installed by a qualified and experienced cladding installer for best results. The information on this page along with all downloads – is to be used as a guide only and for further technical support or advice, please contact our cladding team, prior to placing your order or any installation works.

Explore our Range

NEED MORE INFORMATION

Speak with the ACS project team to learn more about our architectural cladding profiles, finishes, performance, installation process, technical information, price, and any general metal cladding questions you may have.